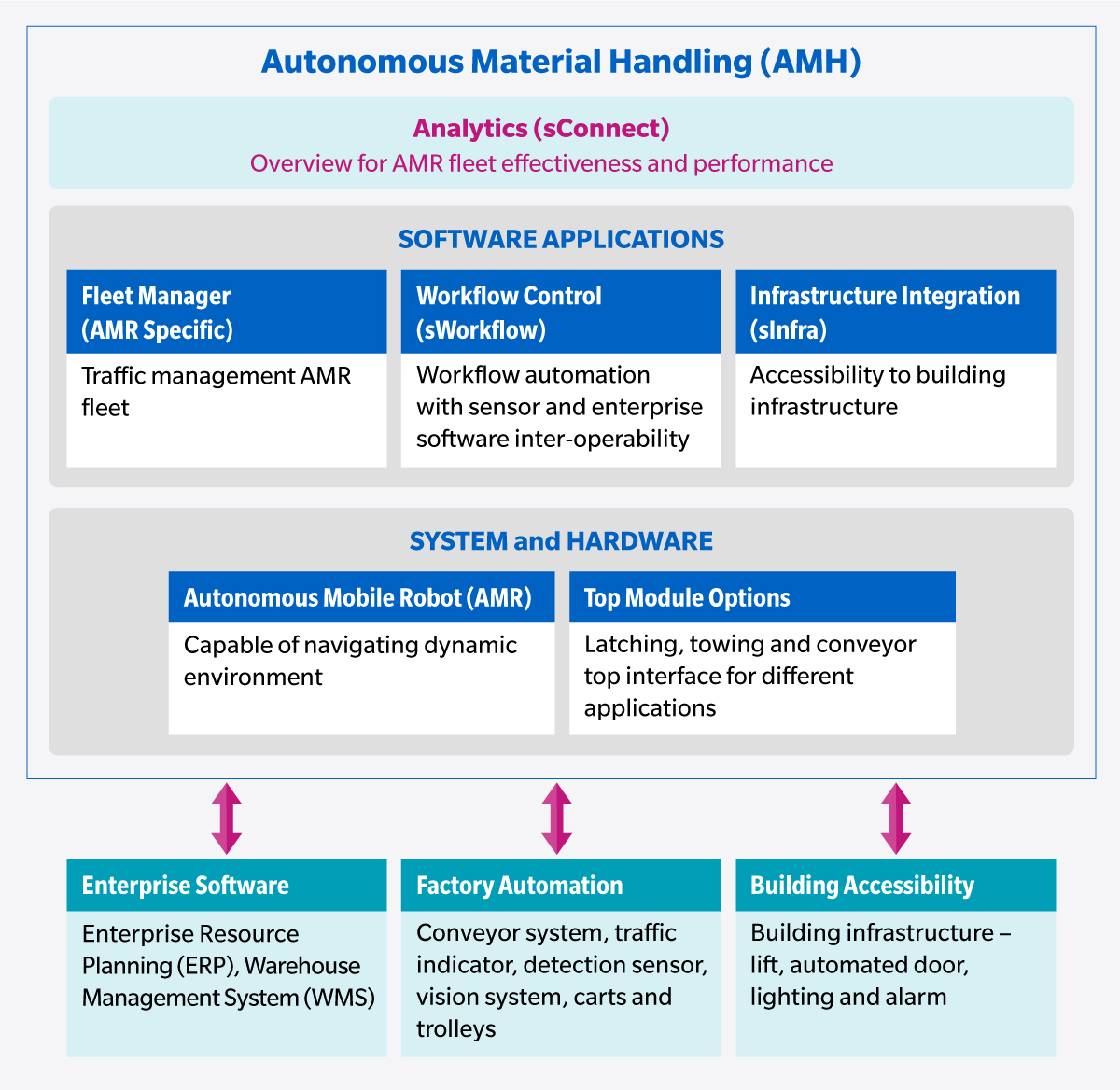

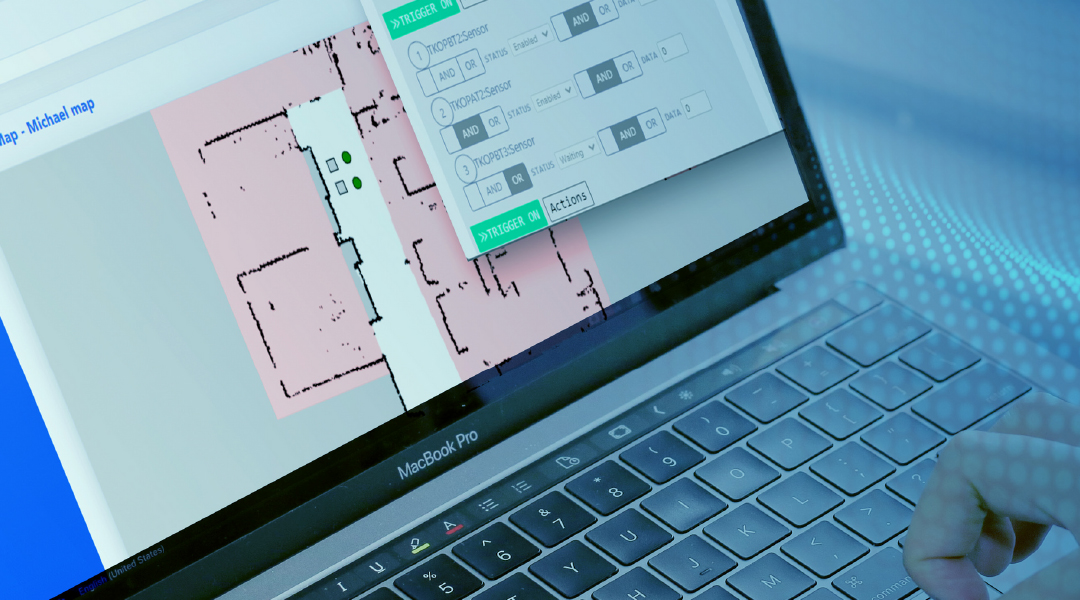

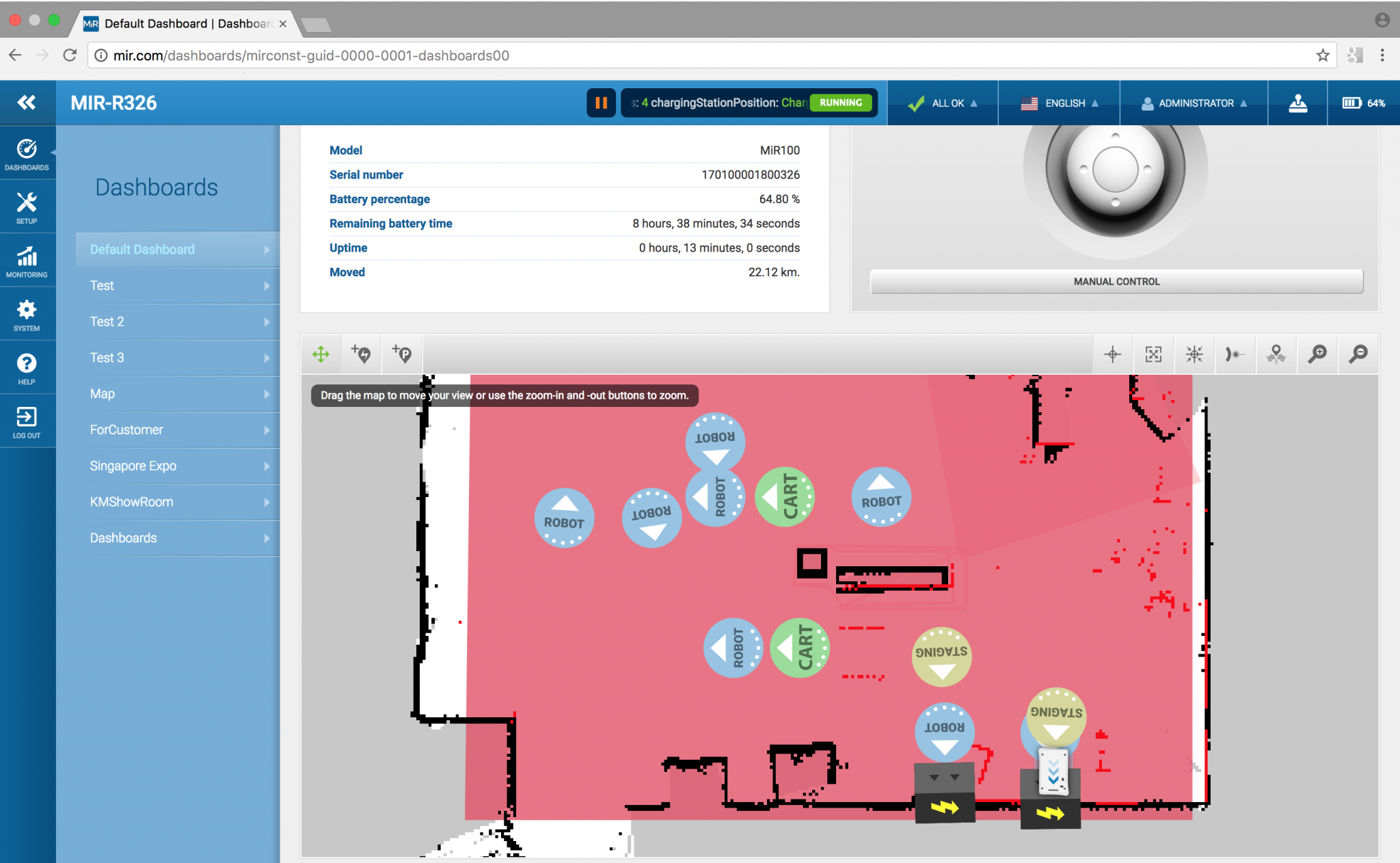

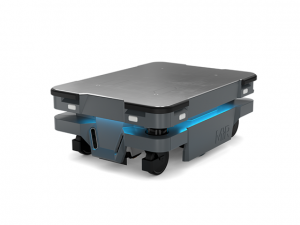

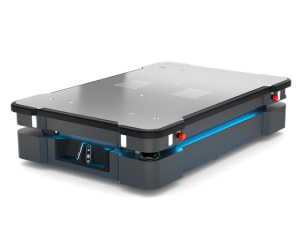

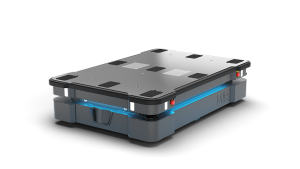

An AMR uses sensors to dynamically navigate any operating environment. Compared to an automated guided vehicle (AGV), an AMR does not need physical or electro-mechanical guidance devices (magnetic tape) and allows navigation route changes using software.

The AMH portfolio uses a wide range of AMR models suitable for different payload needs of pre-break bulk (palletized) and inter-logistic operations. Konica Minolta offers AMRs with payloads from 100 to 1000 kg that can optimize all workflows from the transportation of smaller parts to moving heavy loads and pallets automatically.

The AMH also offers a variety of applications on top of the AMR base unit for different needs to interface with trolleys / carts, conveyors, and robotic arms.